How Fremont became a national hotspot for battery development and manufacturing

You may not know that Fremont is ground zero for the development and manufacturing of next-generation battery technology, but the transition didn’t happen overnight. Instead, it took hard work and perseverance from City officials who created policies and initiatives to help these innovative companies thrive.

Western City Magazine, the League of California Cities’ monthly digital publication, analyzes issues affecting local governance, providing practical ideas, information, and bigger-picture policy issues and trends. In the latest edition, Fremont Economic Development Director Donovan Lazaro penned a guest post for Western City outlining the strategic steps the City took to develop a robust battery development and manufacturing environment in Fremont that continues to flourish today.

Enjoy the full article below.

Over the years, Fremont city staff have amassed unrivaled expertise in understanding the needs of advanced technology industries.

This year, 84% of new electric generation capacity in the U.S. will come from clean energy, with two-thirds likely coming from solar and wind power. More notable, however, is the leap in grid-scale battery installation. Over 16.5% of new generation capacity is anticipated to come from batteries, going from relatively nonexistent just a few years ago to now surpassing the new natural gas generation in the US.

Today, nearly 50 battery or clean energy technology companies can be found in Fremont.

While the sudden surge of battery adoption may seem like it arrived overnight, it comes after years of painstaking efforts by countless startups — many of them in Fremont — to develop new battery cell architectures and the even more challenging process of producing these battery cells at scale.

Over the years, Fremont city staff have amassed unrivaled expertise in understanding the needs of advanced technology industries, including permitting their highly complex operations and providing programmatic oversight for hazardous material management. For battery technology upshots, this expertise has proven particularly valuable.

With the climate crisis worsening, more local efforts like this are needed, be it for battery development or other types of clean energy technology. While not every community can capture investment from the present cleantech boom, Fremont (pop. 230,504) can provide a model for other cities looking to develop their own industry clusters.

Fremont has witnessed, weathered, and benefitted from shifts in semiconductor manufacturing, solar technology, and other industries.

Equipping Fremont to support a thriving battery industry

Fremont has seen its share of manufacturing boom and bust cycles, starting with the General Motors/NUMMI plant, which opened in 1962 and ran 48 years before shuttering in 2010. In the intervening years, Fremont has witnessed, weathered, and benefitted from shifts in semiconductor manufacturing, solar technology, and other industries.

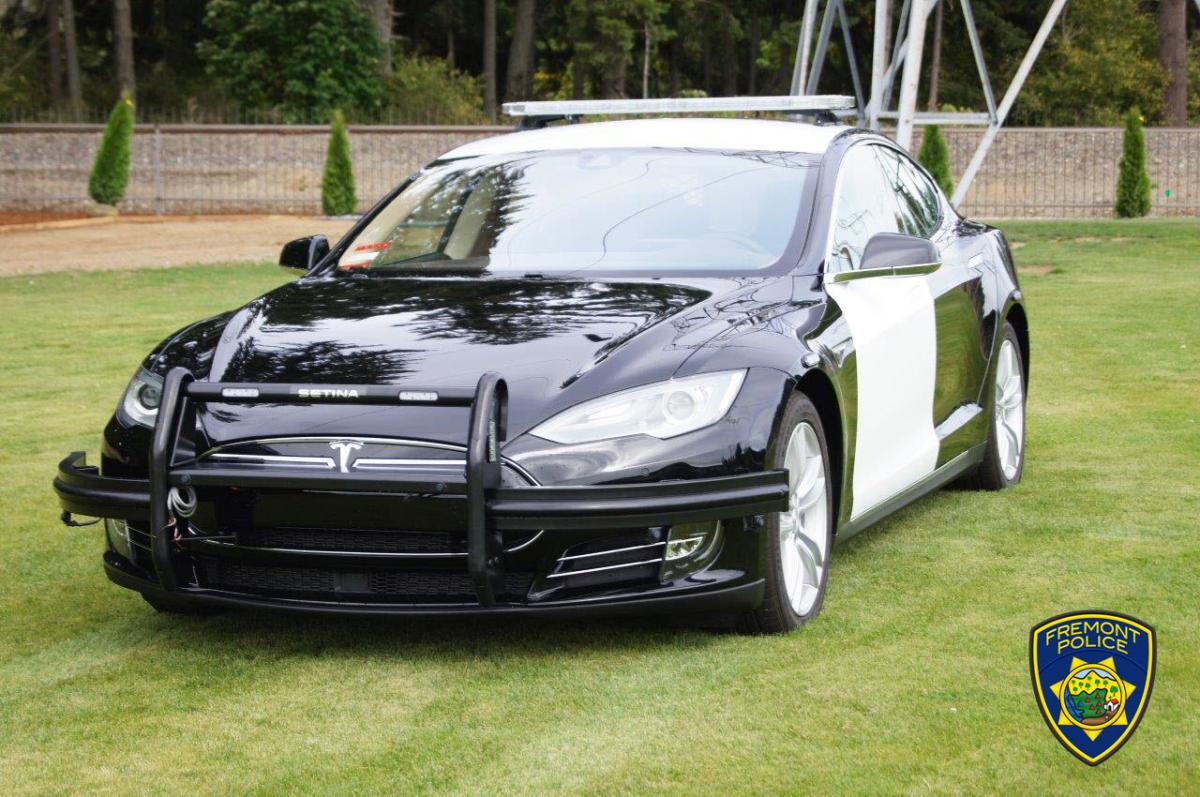

Fortunately, neither the city nor its industry base remained static. NUMMI’s closure paved the way literally and figuratively for Tesla to become what it is today. Soon after its closure, the plant reopened as the Tesla Factory. In 2022, the factory became the highest output auto plant in North America, with Tesla growing its Fremont workforce to over 30,000 employees — a 100-fold increase over 12 years. Facilitating this exponential growth was a significant undertaking and priority for the city, with the company submitting as many as a dozen new construction permit applications on a single workday.

While unmatched in size or stature, Tesla is only one of the hundreds of advanced manufacturing companies in Fremont, often referred to as the city’s “manufacturing ecosystem.” This ecosystem is the result of focused efforts by the city to develop and maintain policies that support the industry, including modernized zoning laws that facilitate emerging industries, investments in the permit review process and staff training, and innovative workforce programs that meet businesses where they are.

After manufacturing at the NUMMI plant resumed, Fremont quickly mobilized to make all aspects of the electric vehicle industry — manufacturing, research and development, sales, service, repair, and charging hubs — allowed by right across the city’s industrial zoning districts. The guiding philosophy was simple: The city wanted to capture as much investment from this budding industry as possible, so removing regulatory barriers within the city’s local control was an obvious place to start. As Tesla suppliers, competitors, and new cleantech startups began to look toward Fremont, the city extended those allowances to encompass nearly all facets of the cleantech supply chain, including batteries.

The city’s industry-recognized hazmat program also played a critical role in attracting new battery startups. In 1997, Fremont became one of the first cities to administer its own state-certified Hazardous Materials Management (CUPA) program, a decision to retain local control for the benefit of its manufacturing sector.

This commitment brought seven separate state and federal regulatory programs in-house with centralized government accountability, allowing applicants to work collaboratively with the city’s fire prevention staff. Fremont remains one of a handful of regional cities to administer its own CUPA program, which continues to be a key part of its business attraction and retention strategy.

To alleviate costs for manufacturing businesses operating at scale, Fremont also maintains a low city business tax and does not have a utility user’s tax or a construction tax on tenant improvements.

To provide contemporary space for manufacturing companies, the city established objective development criteria to allow for simple, ministerial, staff-level design reviews of new industrial projects. This has resulted in over 2.5 million square feet of new industrial buildings in the last several years. The city also ensures that incompatible uses do not encroach into industrial areas, a strategy critical for battery companies looking to scale operations.

The results have been astonishing. Today, nearly 50 battery or clean energy technology companies can be found in Fremont. Amprius moved its headquarters to Fremont and has begun delivering its first batch of ultra-lightweight lithium-ion cells for use in aerospace applications. High-flying EnerVenue has begun operating a 64,000-square-foot headquarters and manufacturing facility in Fremont and is already bursting at the seams. Enovix, which pioneered “3D cell” technology and highly specialized production processes for its batteries used in consumer electronics, achieved its first customer shipments last year.

The city has embraced public-private technology demonstration projects to support its advanced industries and meet its own sustainability goals.

Championing Fremont’s cleantech industry with community stakeholders

Fremont’s extensive battery and cleantech industry cluster would not have been possible without being within the orbit of Silicon Valley. However, it is also the result of years of efforts to position Fremont as Silicon Valley’s advanced manufacturing powerhouse.

Maintaining this position in an ever-changing political and economic climate requires building connections with the greater community so that they are also invested in these industries’ success. City staff regularly connects cleantech companies with elected representatives and policymakers at the local, state, and federal levels to demonstrate the opportunities these industries pose and help policymakers better understand their needs first-hand.

Fremont also hosts one of the largest National Manufacturing Day events in the country, which extends to an entire week of tours at leading companies for K-12 students, adult learners, college students, and Regional Occupational Centers and Programs participants.

This commitment to a highly skilled workforce is not just a one-week event. The city partners with employers and educational providers, particularly Ohlone College, to deliver innovative workforce development programs that jumpstart a new career in advanced industries. The programs often help open the door for historically underserved populations to middle-income careers by catering to people without a college degree, who are not English proficient, or who have lower incomes.

The city has also embraced public-private technology demonstration projects to support its advanced industries and meet its own sustainability goals. The city uses technology from Fremont companies to run three of its fire stations on microgrids. Currently, Fremont is evaluating local companies for city vehicle fleet mobile charging technology demonstration projects; it recently announced a partnership with Fremont-based Gridscape Solutions and East Bay Clean Energy to power more critical facilities on microgrids.

The city partners with employers and educational providers to deliver innovative workforce development programs that jumpstart a new career in advanced industries.

Adapting with the industry to stay ahead of the curve

The former NUMMI plant is symbolic of the city’s decades-long commitment to its manufacturing ecosystem during booming and contractionary periods alike, which continues to pay off in unexpected ways. As a sign of resilience, Fremont’s resurging semiconductor industry is benefiting from the CHIPS and Science Act and shifting geopolitics. And while the solar panel manufacturing industry largely moved offshore, it provided the foundation for Fremont to transition into a national leader in related clean energy technologies, with industry-leading companies like Enphase and Nextracker headquartered in Fremont.

The city has successfully supported these industrial transitions through its hiring practices. New staff are often hired and trained for their abilities to review complex plans from manufacturing companies. As new industries such as batteries emerged, staff become versed in those industries to stay ahead of the curve. Central to this effort is the city’s culture, which has long embraced a collaborative dynamic between its development services and economic development functions.

While there are many challenges ahead in building a sustainable future, Fremont is proud of the role it plays as a leader in the growth of American battery technology and stands ready to support future waves of energy innovation.

© 2023 Western City magazine. All rights reserved. Reprinted with permission from the May 2023 issue of Western City magazine, the monthly publication of the League of California Cities. For more information, visit www.westerncity.com.